|

|

Chrysler Group has confirmed that it will

invest $179 million to launch production of

Fiat's 1.4 litre FIRE engine fitted with

MultiAir at its Global Engine Manufacturing

Alliance (GEMA) plant in Michigan to be

fitted in the Fiat 500 from the end of next

year. |

|

|

|

Chrysler

Group has presented its plans to invest $179 million to

launch production of Fiat's 1.4 litre FIRE engine fitted

with MultiAir at its Global Engine Manufacturing

Alliance (GEMA) plant in Michigan to be fitted in the

Fiat 500 from the end of next year. The investment say

Chrysler will create up to 573 new jobs industry-wide,

including up to 155 new Chrysler Group jobs.

GEMA was up

against building the engine in Mexico, where the 500 is to

assembled although this option is regarded as mainly having

being in play to extract a tax credit out of the Michigan

authorities. Production of the engine next year will trigger

an increase of Fiat's 20 percent stake in Chrysler Group.

The GEMA plant,

located in Dundee, Michigan, will produce the 1.4-liter,

16-valve Fully Integrated Robotized Engine (FIRE) for use in

the Fiat 500 as well as future Chrysler Group vehicles. FIRE

is a collaboration between Chrysler Group and Fiat

powertrain groups and will include Fiat’s innovative

advanced technologies to reduce engine emissions and improve

fuel economy.

“This is one

more important step forward that demonstrates our intent to

deliver on the promise of the Fiat-Chrysler strategic

alliance and the substance of the road map we laid out in

November,” said Sergio Marchionne, Chrysler Group LLC Chief

Executive Officer.

“This project

further demonstrates that Michigan has the competitive

business climate, infrastructure and talented workforce to

compete in the global marketplace,” said Governor Jennifer

M. Granholm.

"We are pleased

and excited with the I-4 FIRE engine loading at GEMA. The

UAW is committed to working with the Company to continue

doing everything we can to ensure this new engine launch is

successful." said General Holiefield, Vice President and

Director of the UAW, Chrysler Department.

Today’s

announcement follows a thorough site selection review by the

company and actions by the Michigan Economic Development

Corporation and the Village of Dundee in support of

the project. Production of the 1.4-liter engine at GEMA will

begin in the fourth quarter of 2010. The first application

of the engine will be in the North American-built Fiat 500

that will go into production in 2011.

Chrysler Group

has two plants at the GEMA complex, located at 5800 North

Ann Arbor Road outside Dundee. In addition to the South

plant which will produce the FIRE, the North Plant, opened

in October 2005, produces the World Gas Engine, Chrysler

Powertrain’s naturally-aspirated, four-cylinder engine

family.

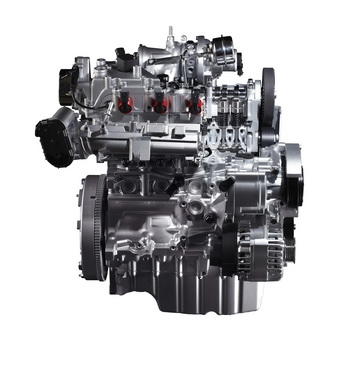

Fiat Powertrain

1.4 liter FIRE engine

Chrysler Group

LLC will debut Fiat’s 1.4-liter, in-line four-cylinder Fully

Integrated Robitized Engine (FIRE) featuring Multiair in the

Fiat 500 starting in 2010. The engine, well-suited for a

small car application, delivers 100 horsepower (75 kW) at

6,750 rpm and 95 lb.-ft. (129 N•m) of torque at 4,250 rpm. A

turbo version also will be available in future applications.

The 1.4-liter FIRE features Fiat’s Multiair technology,

which significantly reduces emissions while improving fuel

economy and power delivery.

The 1.4-liter

FIRE features four valves per cylinder and incorporates

state-of-the-art technology for Fully Variable Valve

Actuation (FVVA), also known as MultiAir. MultiAir is a

sophisticated technology that delivers an increase in power

up to 10 percent and a reduction in fuel consumption and

emissions up to 10 percent when compared to similar engines.

A turbo version of the engine is also planned and will

produce a fuel economy improvement up to 25 percent when

compared to a V-6 engine with equivalent power.

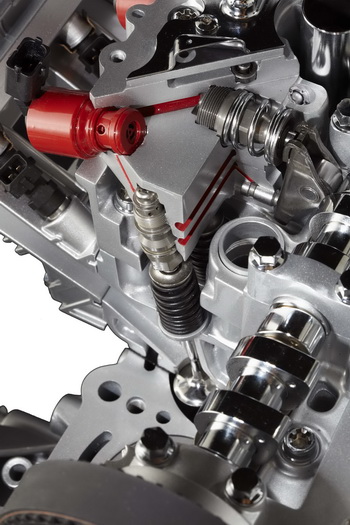

The MultiAir

system consists of electro-hydraulic variable valve

actuators filled with conventional oil, which is interposed

between the camshaft and each valve. A solenoid valve is

energized every 360-degree camshaft rotation, regulating the

quantity of oil addressed to the actuator or to a reservoir.

The lift of the valve is a function of the quantity of oil

addressed to the actuator, ranging from full lift to

complete valve closure. Each solenoid valve may also delay

application of the actuator in advance, leading to late

valve opening or early valve closing. MultiAir is exclusive for Chrysler Group in North America and is based on a

series of Fiat Powertrain patents related to hardware, combustion strategies and

controls that allow for full control of the lift and timing of engine valves.

In the early

1970s, robotics in assembly plants was not common. The term

“FIRE” came into existence when Fiat integrated the use of

robotics in the production process of manufacturing plants.

Although mechanized assembly is commonplace today, the brand

name FIRE has remained with Fiat’s powertrain lineup. The

1.4-liter FIRE with Multiair is the world's first mass

production engine to incorporate such technology to control

the intake valves. Dedicated components have been developed

to accommodate four "bricks" (one for each cylinder), which

package relevant components. MultiAir technology can be

adapted to different types of engines, including Diesels for

enhanced NOx control, and is planned for Chrysler

Powertrain's four-cylinder World Gas Engine and all-new

Pentastar V-6.

|