20.09.2002 FIAT TO INTRODUCE SECOND GENERATION 1.3 16V JTD MULTIJET ENGINE

|

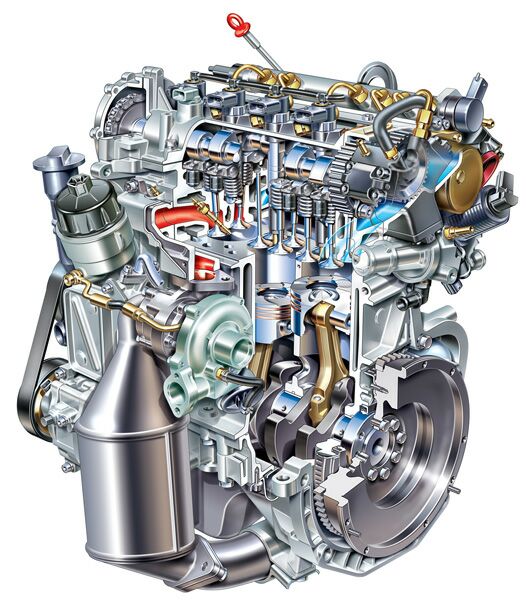

| the all-new 1.3 16v JTD

compact engine

In 2003, Fiat Auto will be adding a revolutionary engine to their range, which aims to move forward common rail turbodiesel technology, by offering better performance, lower fuel consumption and will be more "environment friendly." Developed jointly with General Motors, it is one of the first fruits of Powertrain, the joint GM-Fiat parts development programme. It is expected to be introduced on the facelifted Punto due out next summer, the Panda/Seicento replacement, code name "new small" which debut's in September and later in the year on the new Lancia Y. Across the board Fiat expect its characteristics to allow it to be fitted to larger models, including the Alfa Romeo 147 and Fiat Stilo. The new engine, to be known as the 1.3 JTD 16v, offers two new features: extremely compact dimensions that enable it to be fitted on small cars; and the sophisticated Multijet technology of second generation JTDs. The latter, in particular, is a result of the work of the Fiat Research Centre which was the first to develop the Unijet-type common rail principle, first seen in 1997 on the Alfa 156 JTD, the first car in the world to be fitted with the revolutionary 1.9 JTD 8v. Since then, Fiat's research arm, has continued to investigate the future potential of the common rail injection system and has developed a second generation of JTD engines, the Multijet and multivalve. The outcome is a very compact engine, 460 mm long, 500 mm wide and 650 mm high, with a capacity of just 1251 cubic centimetres and a 16 valve four cylinder in line composition. The unit's highly flexible structure also means it will be possible to adapt it for different applications. Fiat have particularly worked to reduce fuel consumption, a 10% figure believed to have been reached and the unit is designed to reduce noise levels as far as possible. Emission levels will drop by about 30 to 40%, bringing the unit to within EURO IV limits. These results highlight the great technological leap achieved by this new power unit generation. They are better than conventional prechamber diesel units, but also improve on up-to-date Unijet turbodiesel engines with their sophisticated Multijet injection technology and electronic control unit. The control unit increases the number of injections during each cycle to a level higher than the current number of two. In this way, the same amount of diesel is burnt inside the cylinder but split to achieve smoother combustion. The 1.3 JTD 16v will be built by Powertrain, the joint GM-Fiat company at the Polish plant of Bielsko-Biala. engine The 1.3 JTD 16v Multijet is a 1251 cc four cylinder in-line power unit with a bore of 69.6 mm and a stroke of 82 mm. The four valves per cylinder are operated directly by a twin overhead camshaft system. Maximum power is 70 bhp for a torque of 170 Nm. The new power unit features a chain-driven timing system with fingertip control, hydraulic tappets, a cast iron crankcase with an aluminium base and an aluminium cylinder head. The cylinder head is also designed with highly efficient directional intake ports to ensure an optimum fuel mix despite the small bore. The 1.3 JTD engine is turbocharged by a turbocharger with wastegate and intercooler. A variable geometry version will also be available shortly. The power unit also features an electronically-controlled EGR system and an exhaust gas cooling device. the Multijet system The second-generation 1.3 JTD engine employs a Multijet system based on the common rail principle. This uses electronic injector control to carry out more injections than the current number of two during each engine cycle. In this way, the same amount of diesel is burnt inside the cylinder but in smaller parts to achieve smoother combustion. The secret of the Multijet system lies in the design of the control unit and injectors designed to deliver a series of very closely spaced injections. Fiat Auto researchers developed this injection process to ensure more accurate control of pressures and temperatures inside the combustion chamber and more efficient use of air taken into the cylinders. The Multijet is based on a very simple engineering principle. Present-day common rail engines already carry out a pre-injection or pilot injection to increase temperature and pressure in the cylinder for more gradual combustion and a quieter running engine. The new system goes on to divide the main injection into smaller injections so we can achieve more ambitious goals: quieter combustion, reduced emissions and increased performance. The system offers considerable benefits that can be applied to optimise different individual engine service strategies. In some cases, for example, the priority is to reduce start-up times and fume levels, in other cases it is to increase torque and reduce noise while in others it is to reduce emissions and ensure a quieter drive. buliding on diesel expertise The new Multijet system has allowed the Fiat Group to achieve an important new record in the diesel engine field. Fiat have been building up know-in this field since 1986, when the Croma TDI, the first direct injection diesel vehicle in the world, was introduced. The Croma engine was a success and the first major step toward automotive diesel engines with more efficient combustion. The engineering, subsequently copied by other manufacturers, meant that diesel cars were able to ensure better performance coupled with lower fuel consumption. One problem remained: excessive engine noise at low rpms and during speed transitions. This was the cue for the start of the Unijet story, i.e. the quest for a more advanced direct injection system that could drastically reduce the problem of excessive combustion noise. Some years later, this research strand brought Fiat the Unijet itself and significant benefits in terms of efficiency and fuel consumption. Fiat's engineers reasoned that the problem could be resolved in one of two ways: they could be content with a passive system and simply insulate the engine to prevent sound waves from reaching the passenger compartment, or they could work actively to eliminate the problem at its source by developing an injection system that actually reduced combustion noise. Fiat Group engineers went for the second option and immediately chose the common rail principle after considering and then rejecting other high-pressure injection systems which do not allow pressure to be managed independently of rpm and engine load and fail to include a pre-injection, which is an essential attribute of the Unijet system. The theory that lay behind their research was originally developed by researchers at Zurich University but had never previously been applied to a vehicle. This simple theory is based on the assumption that if you continue to push diesel into a tank, the pressure inside will rise and the tank itself will become a hydraulic accumulator, or rail, i.e. a reserve of pressurised fuel ready for use. Three years later, in 1990, the Unijet system was developed by Magneti Marelli, the Fiat Research Centre and Elasis and the common rail principle entered the pre-production stage. This stage was completed in 1994, when Fiat Auto started to look for a partner with in-depth knowledge of diesel engine injection systems. The final stage of the project, i.e. completion of development and industrial production, was eventually entrusted to Robert Bosch. In October 1997, eleven years after the Croma TDI, Fiat introduced another new-technology car: the Alfa 156 JTD. The new model was equipped with a revolutionary turbodiesel engine that was to deliver previously unattained results. Vehicles equipped with this engine are incredibly noiseless with all the dynamics of a petrol power unit. They improve on the performance of a similar prechamber engine by an average of 12 percent and reduce fuel consumption by 15 percent. The Alfa 156 equipped with a JTD engine won immediate approval and similar power units soon appeared on other Fiat Auto models and were adopted by many other motor manufacturers. Now comes the second generation of JTD engines, the Multijet units. Tthe 75th Paris Motor Show next week is the setting for the world premier of the 1.9 JTD 16v multiple injection fitted to Alfa 156 and 147 models, the first engine of this type. And next year the small 1.3 JTD 16v Multijet unit will debut. |

|

technical data:

|

|

| related articles:

18.09.2002 ALFA ROMEO TO UNTRODUCE NEW 140 BHP 16V 1.9 JTD ENGINE AT PARIS MOTOR SHOW |

| <<< return to news index |