|

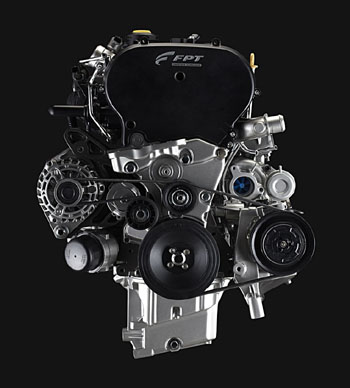

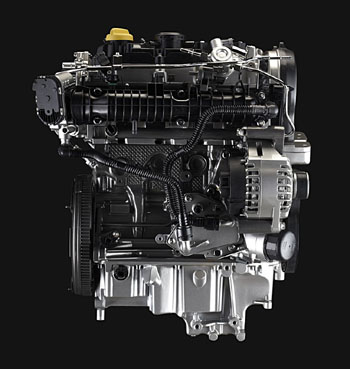

THE STRENGTHS OF

THE NEW ENGINE

|

|

The entire world

acknowledges the

fact that the

Italian motoring

school has always

had the ability to

produce gritty and

temperamental

engines, true

"jewels" that are

the result of the

experience and

passion of the

engineers matched

with their technical

competencies

acquired over years.

The new 200 HP 1.8

Di TurboJet (Euro 5)

is no exception.

The new engine is

produced by FPT –

Fiat Powertrain

Technologies - and

has a maximum power

of 200 HP (147 kw)

at 5,000 rpm and a

maximum drive torque

of 320 Nm (32.6 Kgm)

at 1,400 rpm. Thanks

to its combination

with a 6 gear

automatic/sequential

transmission, the

200 HP 1.8 Di

TurboJet provides an

exciting and

unmatchable drive:

it can reach a

maximum speed of 230

km/h and accelerate

from 0 to 100 km/h

in 7.4 seconds. In

spite of these

amazing

performances, fuel

consumption and

emissions are

surprisingly low:

respectively 7.8

l/100km in the

combined cycle and

185 g/km of CO2.

Thus, these

innovative engines

prove Lancia

Automobiles'

commitment to

protecting the

environment by

containing emissions

as well as reducing

fuel consumption.

All this is achieved

by enhancing

brilliance,

flexibility and the

pleasure of driving

which have always

made this model

stand out. In order

to achieve these

extraordinary

results, the 200 HP

1.8 Di TurboJet

introduces petrol

direct injection,

turbocharging and an

exhaust and intake

double continuous

phase transformer.

The merging of these

different

technological

solutions offers

important advantages

to clients such as

the direct injection

which means low fuel

consumption for high

engine performance.

Furthermore, the

turbocharger

associated with the

double phase

transformer enables

quick acceleration

thanks to a

particularly

favourable drive

torque curve.

Here are the details

of all the

innovations of the

new 200 HP 1.8 Di

TurboJet which was

designed and

developed by

engineers of FPT -

Fiat Powertrain

Technologies, the

sector of Fiat Group

that provides

innovation, design,

plan and production

activities for

engines and

gearboxes of all

uses: from cars to

industrial vehicles,

from boats to

agricultural

machines. With about

20,000 employees, 16

plants and 11

research centres

located in 9

different countries,

this Sector

represents a most

significant presence

in the field of

engines at world

level. In FPT, about

3,000 highly

specialized

engineers work on

innovation

technologies

development and

automation. The over

40 patents

registered every

year show quality

and reliability of

this group, making

FPT – Fiat

Powertrain

Technologies - a

great centre of

technological

excellence and

constant innovation.

The Scavenging

Technology

The amazing

performances of this

engine are a result

of the application

of the Scavenging

technology which

maximizes the drive

torque at very low

rpm by guaranteeing

an incredible engine

response speed to

any driver request.

Scavenging can be

obtained by

controlling and

optimising at every

instant engine

parameters such as

dosage, position of

the two phase

transformers,

ignition advance and

injection timing.

Basically, it is

possible to define

the angle and

overlapping time of

the valves with

extreme precision in

order to generate

direct air flow from

the intake to the

exhaust manifolds

and start the

turbocharger in very

short times. This

means the engine can

make better use of

the supercharging

when compared to

standard

turbocharged petrol

engines. The system

is managed by an

innovative engine

management control

unit integrating an

extremely modern

software which

manages all

parameters. The

result is

remarkable: the

maximum drive torque

at 1,400 rpm

increases by 70%

compared to

traditional turbo

engines and response

times are halved,

getting close to

those of aspirated

engines.

Direct injection

The direct injection

reduces the

temperatures in the

combustion chambers

through the

evaporation of fuel

and lowers the knock

sensitivity. This

enables the engine

to achieve great

performances even

for a moderately

high compression

ratio (equal to 9.5)

and ensures limited

fuel consumption at

a "partial" speed.

The direct

injection system is essential in reducing emissions thanks

to an advanced strategy of double injection. Furthermore,

thanks to the direct control of fuel, it is possible to

avoid some of the petrol getting directly to the exhaust

manifold during the scavenging with negative effects on the

catalytic converter's functionality.

|

|

|

|

|

Lastly, this injection system of second generation is

provided with a new high pressure pump (capable of managing

petrol pressure of 150 bar) and innovative injectors with 7

holes that guarantee ideal evaporation for all operating

conditions.

Double phase

transformer

The two continuous

phase transformers

on the intake and

exhaust camshafts

enable phase

optimisation at any

speed and engine

load by reducing

fuel consumption and

emissions as much as

possible. Moreover,

by combining the two

transformers with

the turbocharger, it

is possible to

manage the

Scavenging strategy

by defining the

correct overlapping

during the

transitory phases.

In this way it is

possible to respond

to a sudden driver

request by

maximising the

engine's response

speed at low rpm.

Turbo

This engine is

provided with a new

generation

turbocharger

connected to an

innovative “Pulse

Converter”-type

exhaust manifold

which optimises the

use of exhaust

pressure waves to

increment the

driving torque at

low speeds. Both

manifold and turbine

are made of

microcast steel so

that they can reach

very high working

temperatures (up to

a maximum of 1020

°C). This is very

important for

reducing consumption

while operating at

medium/high speed -

i.e. on a motorway.

Thermal Fluid

Dynamics

The intake ducts

were designed and

optimised by using

mono and

three-dimensional

calculation

technologies through

which it was

possible to obtain a

correct and high

turbulence level.

Even the combustion

chamber was

optimised by using

wide squish areas

and by minimising

area/volume ratios

with clear benefits

in terms of

combustion

efficiency. Lastly,

the exhaust ducts

were designed to

work in tune with

the exhaust manifold

and maximise its

pulse converter

effect.

“Friction”

The entire engine

was made with the

aim of minimising

friction losses. The

pistons are provided

with piston rings

with a reduced

tangent load and are

made of advanced

materials to

minimise wear and

tear. Furthermore,

the engine cylinder

head was designed

with two roller

rocker arms placed

on the valve control

which reduce losses

by friction of 65%

at 2000 rpm compared

to direct command.

This is a typical

solution adopted for

Brand Premium

engines.

The mechanic

optimisation with

very long rods

combined with a

moderately short

travel has resulted

in a drop of

vibrations which are

typical of four

cylinder engines

operating at very

high speeds. As it

wasn't necessary to

utilize balancing

countershafts, the

weight was further

optimised and

consequently, the

fuel consumption was

reduced.

Performances

The Scavenging

strategy combined

with the innovative

control system has

allowed this engine

to reach new

benchmarks in terms

of performance. The

specific drive

torque (185 Nm/l) is

extremely high, one

of the highest among

the engines

available nowadays.

Furthermore, we can

confidently say that

the maximum drive

torque value (320

Nm) achieved at 1400

rpm represents a

point of absolute

excellence. This

value ensures

excellent

performances in

terms of

acceleration and

allows a greater car

response without

having to change

gear frequently.

Lastly, the high

specific power of

115 HP/l can be

reached at a

relatively low speed

of 5,000 rpm and

remains constant up

to 5,500 rpm.

In brief, the 200 HP

1.8 Di Turbo Jet E5

drive torque is

comparable to the

one of an aspirated

V6 engine which is

almost twice its

displacement.

However, thanks to

the downsizing

philosophy, it was

possible to reduce

the weight with

great efficiency

benefits.

Emissions

One of the main

priorities of FTP –

Fiat Powertrain

Technologies -

engineers was to

guarantee a low

level of emissions

together with

excellent

performances, in

line with the Lancia

Automobiles'

philosophy which

places the

protection of the

environment at the

core of its

products' design and

improvement. Just

like the Lancia

Delta diesel engines

(the 190 HP 1.9 Twin

Turbo MultiJet, 120

HP 1.6 MultiJet and

165 HP 2.0 MultiJet),

the brand new 1.8 Di

Turbo Jet 200HP E5

was Euro 5 approved

even before the

standard enforcement

date. |

|